Simple E-Commerce Request Uncovered a Wholesale Business's True Need

What began as an e-commerce project revealed a deeper need: tracking products across the entire supply chain, not just processing orders

December 2022. My phone rang on a quiet morning. A previous client wanted to discuss a new partnership venture that needed "some automation stuff."

Their business model was straightforward enough — wholesale trading of engines and tools for installation professionals. They had supplier relationships and a network of small partners who repeatedly purchased their products.

He laid out their situation:

"Here's our problem: All our sales happen over the phone. Customers call the manager, ask what's available, negotiate prices, and place orders. We need a simple internal e-commerce site so they can serve themselves."

It sounded like a standard project — nothing I hadn't handled before.

The False Start

I began with efficiency in mind, researching no-code and low-code platforms that might give us a quick win. I tested several promising options, each offering drag-and-drop interfaces and pre-built e-commerce components.

But as I dug deeper, limitations emerged. The platforms were too generic for their specific pricing rules. Customizations that should have been basic required premium subscriptions. Integration options felt restrictive.

After days of evaluation, I realized a surprising truth: building custom would be faster than configuring existing platforms. A Next.js frontend with Airtable as the database and Auth0 for authentication would give us complete control without complexity.

This decision to go custom rather than pre-built would prove fortunate when we discovered what the business really needed.

Building the Foundation

The technical architecture came together smoothly:

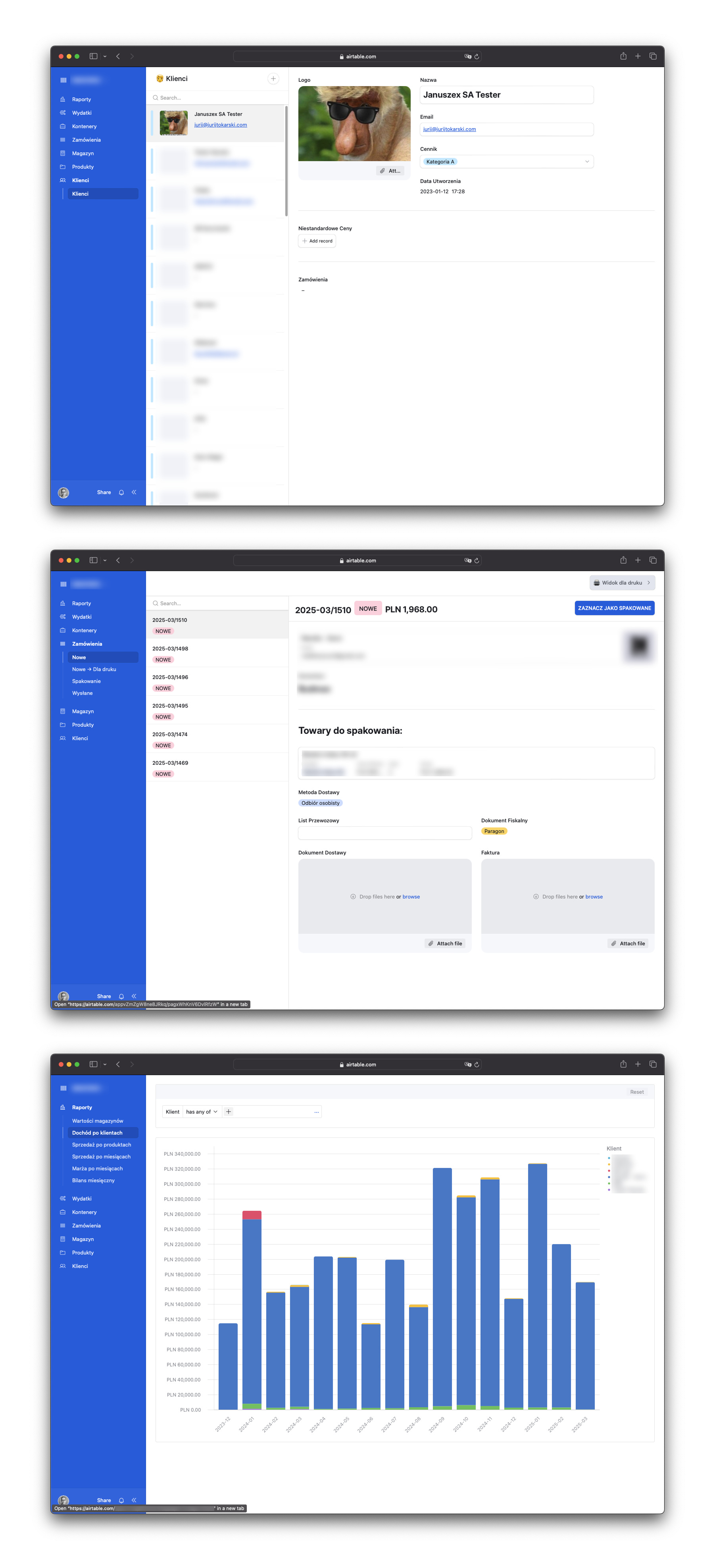

Client maintained customer records in Airtable

Website credentials generated automatically

Customers logged in to browse products and view order history

Orders placed through a simple virtual cart

No payment or shipping integration needed

Manager handled order fulfillment offline

The interface was clean and focused on exactly what their customers needed – nothing more, nothing less.

The Hidden Complexity

Though the frontend appeared simple, the business rules behind it were anything but:

Bundle Requirements: Some products could only be purchased in bundles, with pricing that changed dynamically based on selected complementary items.

Tiered Add-ons: Products offered options ranging from free to premium, with some refusing the free option entirely.

Custom Pricing: Each customer had individualized discount structures calculated in real-time to show accurate final prices.

These requirements would have broken most off-the-shelf solutions, but our custom approach handled them with ease.

The Airtable Command Center

While the website got the attention, Airtable quietly became the operational heart of the business. We created custom interfaces for staff to manage products, monitor orders by status, and maintain website content without developer intervention.

We implemented automations to send email notifications when new orders arrived, update inventory levels automatically, and track changes in order status.

Statistical dashboards gave management insight into sales patterns and costs, all controlled from within Airtable.

The client was delighted. The project appeared complete. We were ready to wrap things up.

The Plot Twist

During what should have been our final meeting, the client asked a question that would reveal the true challenge:

"Can we go beyond the warehouse? Can we automate how items appear in available inventory in the first place?"

That's when we discovered their complete supply chain operated across four distinct stages:

Manufacturing (products ordered but not yet made)

Shipping (en route from country of origin)

Customs (approved but not ready for sale)

Main Warehouse (finally available to customers)

What they truly needed wasn't just an ordering system – it was comprehensive inventory flow management across their entire supply chain.

The Real Solution

Using Airtable's automation capabilities and custom JavaScript scripts that triggered on specific events, we created a solution that tracked products through each stage of their journey.

The system handled each transition automatically:

Manufacturing to Shipping: Scripts calculated transport costs based on weight and added them to product cost

Shipping to Customs: System recorded arrival and prepared for clearance

Customs Clearance: Appropriate tax calculations applied automatically

Final Availability: Staff could selectively move products to the main warehouse, making them available for sale online

This approach gave them something they'd never had before – complete visibility into their inventory pipeline and automated cost calculations at every stage.

The Unexpected Win

What began as a request for "a simple e-commerce site" evolved into something far more valuable: a custom inventory management system that automated their entire business operation.

This project reminded me that the most valuable solution isn't always what's explicitly requested. By choosing flexibility over expedience and looking beyond the initial requirements, we discovered and addressed their true business challenge.

Sometimes the best technology isn't the most complex — it's the one that most precisely fits the actual workflow, even when that workflow wasn't clear at the beginning.

I still maintain the solution, adding refinements as their business evolves. But the foundation remains solid: a custom system that recognized and solved their real business need, not just the symptom they initially identified.